IEULER Testing Center

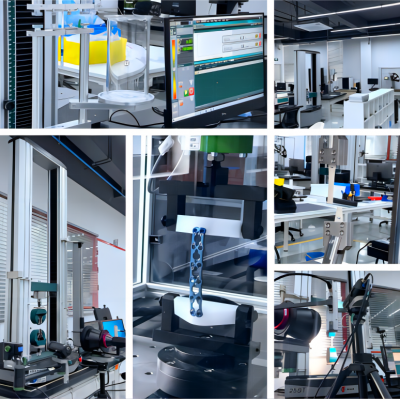

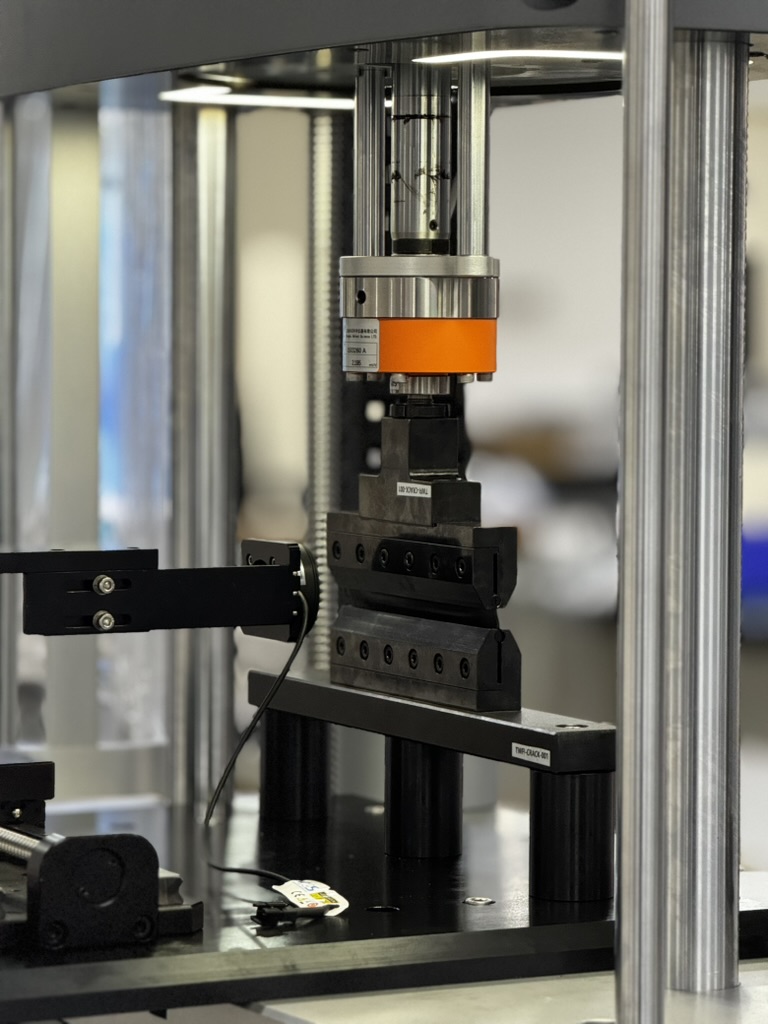

Shanghai Techwin Science Co., Ltd. is holding company of an independent third-party laboratory nearly 1,000 square meters. As a professional Sino-German joint venture third-party testing laboratory in China, it is co-founded by Techwin, and other two Geman Company DYNA-MESS and SpineServ. They run two laboratories together—one in China (Shanghai) and one in Germany. The Shanghai laboratory is equipped with kinds of advanced facilities, including over 50 sets of imported testing instruments and sample preparation machines. Integrating the professional testing technologies support from SpineServ and more than 40 years experience of testing instruments development from DYNA-MESS, our laboratory provides standard testing and customized testing services and various R&D tests for customers, and also provides testing consulting and training.

As a technical platform, IEULER® Polymer Material Application Testing Center of Techwin focuses on the testing and R&D service for rubber and elastomers, plastics, and composite .Notably, it is the first third-party laboratory accredited by CMA (China Metrology Accreditation) in accordance with GB/T 41941-2022 (Determination of Fatigue Crack Growth Rate of Vulcanized Rubber) in China.

Our LaboratoryRigorous, serious, accurate, and reliable

Laboratory Provides

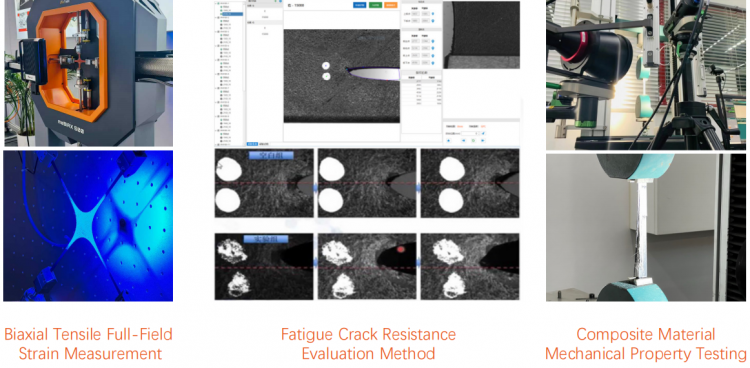

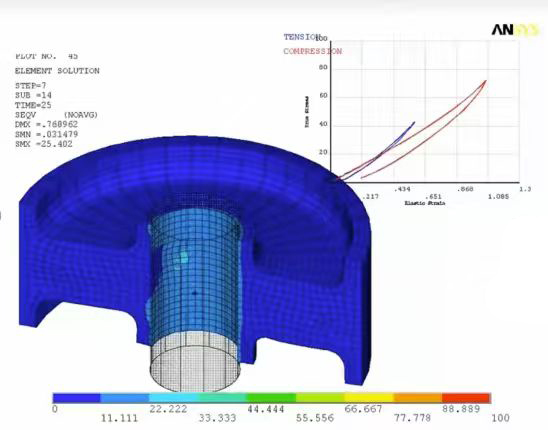

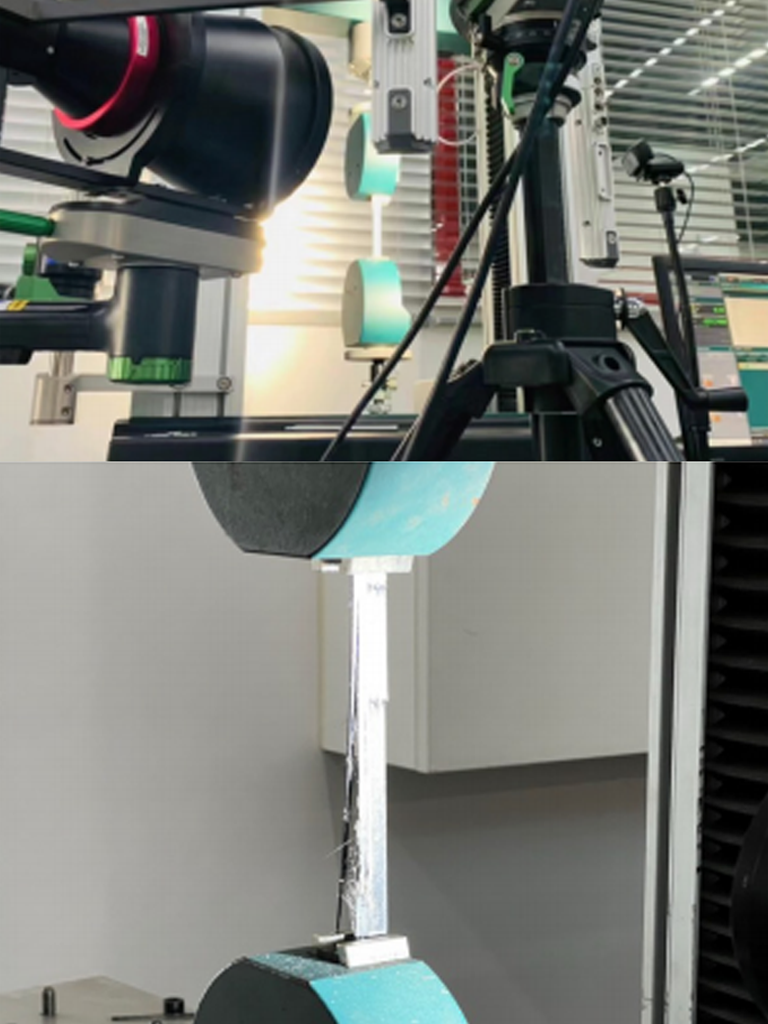

- Testing Elastomers for Material Models in Finite Element Analysis

- Rubber Fatigue Crack Growth Test

- Biaxial Test

- Planar Test

- Planar Test

- S-N Curve

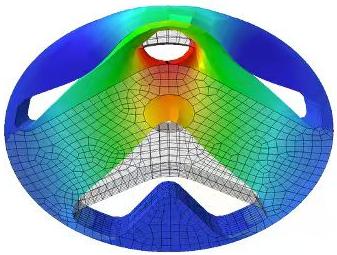

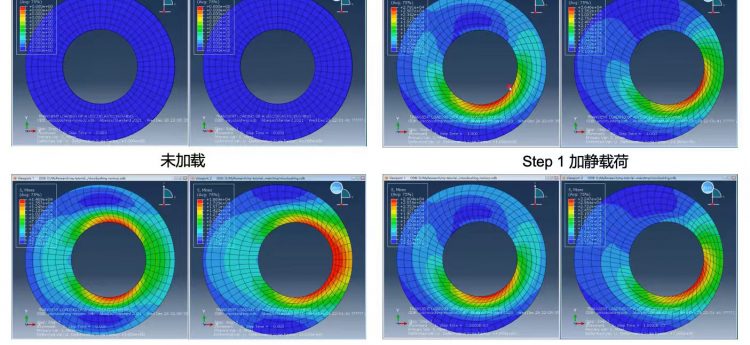

- Finite Element Analysis (FEA) Simulation

- General Physical and Mechanical Properties Testing for Rubber Elastomers (e.g., DMA, RPA,rubber compound flow testing, Mooney viscosity, vulcanization, etc.)

- Laboratory Information Management System (LIMS) Software Development

- Technical Training

- R&D Support

- Recipe Development

- Failure Analysis

Rubber Material Standard Test Parameters

- 300% Modulus

- Compression Set

- Elongation at Break

- Tear Strength

- Storage Modulus

- Loss Modulus

- Mooney Viscosity

- tan δ

- 100% Modulus

- Tensile Fatigue Cycles

Constitutive Relations of Rubber Materials

Rubber Material CAE Simulation Input Parameters

- Hyperelastic Constitutive Model Parameters

- Mullins Effect Model Parameters

- Viscoelastic Constitutive Model Parameters

- Temperature-Dependent Constitutive

- Model Parameters

- Strain Rate-Dependent Model Parameters

- Thermodynamic Model Parameters for

- Rubber Materials

- Fatigue Crack Growth Model Parameters

· · · · ·

Experienced teamWith years of experience helping customers solve material testing problems, we know how to meet your requirements and provide unique testing solutions.

TechWIN has obtained dual certification for CMA inspection and testing institution qualification and ISO9001 Quality Management System!

- Achieving ISO9001 certification is a recognition of the company’s excellence. It demonstrates that the integration of various management systems has reached international standards, ensuring the company can consistently and stably deliver products and services that meet customer expectations and satisfaction.

- Passing CMA certification for external testing qualifications signifies that the laboratory has undergone rigorous accreditation. It is now capable of providing customers with standardized testing, customized non-standardized testing, R&D-related experiments, as well as testing consultation and training services.

Laboratory Honors:

- Vice Chairman Member of the Rubber Testing Committee in China Rubber Industry Association (CRIA) on the 10th Council

- Member of the Subcommittee on General Test Methods (SC 2) under the 8th Session of the National Technical Committee for Standardization of Rubber and Rubber Products (SAC/TC 35)

- Contracted cooperative laboratory of the China Rubber Industry Association (CRIA)

- Cooperative Laboratory of the Subcommittee on General Test Methods (SC 2) under the National Technical Committee for Standardization of Rubber and Rubber Products (SAC/TC 35)

- Advanced Member in Standardization Work of the Subcommittee on General Test Methods (SC 2) under the 7th Session of the National Technical Committee for Standardization of Rubber and Rubber Products (SAC/TC 35)

- Leading Drafter of GB/T 41941-2022 Determination of Fatigue Crack Growth Rate of Vulcanized Rubber